WELCOME TO DMA

Dhartidhan Metal Alloys is prominent manufacturer, supplier & exporter of High-Quality Secondary Zinc Ingots and Brass Billets with wide range of length and alloys as per customer’s requirement.

Our Facilities are capable of handling a wide variety of nonferrous metal, combined with 50 years of experience to handle any job. We service accounts nationally and internationally, and buy material from scrap metal dealer and yard owners throughout the world.

Dhartidhan Metal Alloys have production capacity of 14,000 MT/Annum with the installation of 4 renowned gas melting furnace & 1 induction melting furnace. All products manufactured by us are tested at our alloy testing lab Bruker TASMAN Q4 which is German made. Our manufacturing facility spread over 66,000 sq. feet.

We are proud member of Metal Recycling Association of India (MRAI), Business Networking International (BNI), Naghedi Lakhabavad Factory Owners Association (NLFA), Bombay Metal Exchange Ltd (BME) and Bombay Non Ferrous Metal Association Ltd (BNMA).

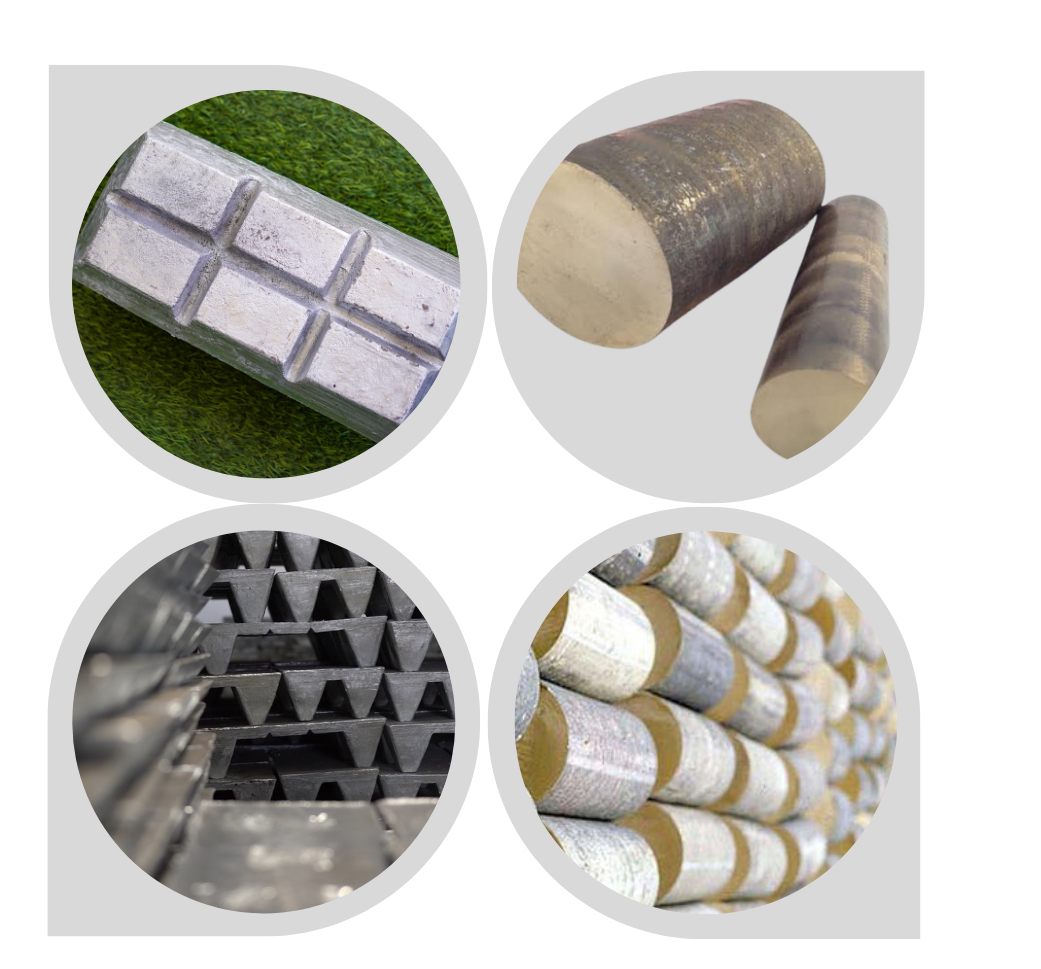

PRODUCTS

Zinc Ingots

Zinc is primarily used for galvanizing steel against corrosion, die casting of intricate machine parts, and in batteries and other electrical applications. Zinc is also alloyed with copper to form brass.

Zinc as a compound is used in pharmaceuticals, rubber, cosmetics, paint, and ceramic glaze. Other compounds use zinc in cathode-ray tubes, soldering flux, and wood preservatives.

Brass Billets

Brass Billets are mainly used in manufacturing brass rods, brass components, bearings, valves, sleeves, sanitary, electrical and automobile industries

International Level PROCESS to Achieve High Quality

Scrap Inspection

Scrap is inspected by well Trained & Qualified Staff

Scrap Separation

Separation of Raw material according to their grade

Scrap Testing

Scrap / raw material's Chemical composition testing by spectrometer

Metal Melting

After testing of raw material, they are melted in Furnace

Selection Of Flux

Appropriate usage of Fluxes to achieve highest precision in manufacturing

Final Product Testing

Final melt is tested by optical spectrometer and casted. Ingots are free from any other impurities and stamped with batch number

SOME STATISTICS

Factory Area

Manufacturing facility spread over 66,000 sq feet

Countries we served

We are serving in more then 15 countries world wide

Client

We have More than 150 customers World Wide

Manufacturing Capacity

We have production capacity of 14,000 MT/Annum

WE ARE HERE

POSTAL ADRESS

Plot no 3, Survey No 231P, 234,235, Lakhabawal, Naghedi, Gujarat, India 361006

WORK HOURS

Mon - Thu 9:00-19:00

Sat - Sun 09:00-19:00

Friday Closed

Contact Details

+91- 93289 78956

EMAIL ADRESS

info@dhartidhanmetal.com

Dhartidhan Metal Alloys

Plot No 3, Survey No 221P, 231& 234, Lakhabawal

Gujarat 361006

India

To KNOW MORE ABOUT US

Download Brochure